Welcome to the TOD blog

Latest blog posts

Event guides, bucket-list adventure guides, gear advice, guides to the best places plus tips and advice on wellbeing and more.

.jpg)

- 10 mins read

Race the Sun | your team guide to riding, hiking and kayaking from dawn to dusk

Ride, hike and kayak to beat the sunset. Learn how it works, dates, locations, team tips and how to enter - then pick your event.

- 15 mins read

Your Guide to Conquering Snowdonia's Best Outdoors Events

Single event or triple challenge? Unleash your adventurous spirit in a legendary landscape.

- 10 mins read

Race 101: the 13 Valleys Ultra

Introducing the 13 Valleys Ultra plus the event's shorter distance options, helping you to push your limits and get involved!

- 10 mins read

The best triathlons in the UK

From beginner races to ultra challenges, swim-bike-runs are the UK's favourite multi-sport events - these are the triathlons that you need to have on your radar.

- 10 mins read

Unforgettable adventures to book this summer

Summer holiday season is upon us and we're rounding up the best overseas adventures that you can book onto right now!

- 10 mins read

The best events in every UK National Park

The UK's National Parks provide incredible outdoor playgrounds - these are the runs, bike rides and swims to help you make the most of these epic spaces.

- 5 mins read

What is the best route to climb Kilimanjaro?

The route you pick for your Kilimanjaro trek will help to determine the experience that you enjoy, from comfortable dorms to wild camping!

- 5 mins read

Best cycling events in the UK

Inspired by the Tour de France? You don't need to ride the Alpe d'Huez to enjoy an epic peloton experience - these British bike rides are the real deal.

- 5 mins read

4 epic hikes to challenge yourself in spring and summer

Make the most of the sunshine with these hikes atop the mountains and coastlines of the UK, all supporting fantastic charity causes.

- 10 mins read

Aim for a new half marathon PB

Looking for a new challenge? Taking on your fastest ever half marathon could be exactly the motivation you need to get out there and be more active outdoors!

- 10 mins read

The best runs that you've never heard of

To celebrate Global Running Day, we're rounding the best unsung marathons, half marathons and more in the UK!

- 10 mins read

8 essentials you need in your hiking bag

Whether you're heading into the great outdoors for a few hours or a few days, these are the essentials you need to guarantee staying safe and having the best experience.

- 10 mins read

The best trail runs this summer

Head off-road and into a world of epic trail running this summer, exploring the mountains, forests and coastlines of the UK.

- 5 mins read

Best autumn half marathons

Enjoy the sensational atmospheres and fast courses at these half marathon races, from the world's biggest half to the UK's fastest half marathon.

- 5 mins read

Top 5 adventure races in the UK

Epic adventure activities, crammed into a race through wild landscapes - what's not to love?

- 15 mins read

7 things we learned from a half Ironman

Humbling and exhilarating in equal measures, a half Ironman triathlon is an unforgettable experience - following these hard-learned tips will make sure that's for all the right reasons.

- 12 mins read

5 ways being active outdoors together can help your team's mental health

This is why an active outdoors challenge is the tonic your team needs to banish workplace anxiety and build a more cohesive culture.

- 8 mins read

10 best ultra marathons in the UK

Take on an epic endurance challenge with one of the most popular ultra runs in the UK, from traditional fell runs to the UTMB World Series!

- 10 mins read

What is the best 10K near me?

6.2-miles is the perfect distance for beginner runners and experienced athletes alike, with hundreds of runs around the UK - find the best 10K in your local region right here.

- 5 mins read

5 everyday adventures to spend more time outdoors

These micro doses of outdoor adventure are enough to sustain your wanderlust between bigger trips to the great outdoors!

- 15 mins read

Your guide to the National Three Peaks Challenge

Take on this iconic challenge in 2023 and make unforgettable memories on the UK's highest mountains!

- 5 mins read

3 family adventures this summer

Get the whole family active outdoors with these epic adventures, ranging from mountain hikes to week-long activity holidays!

- 5 mins read

10 best autumn marathons

Looking for a fresh challenge this year? Sign up to an end-of-season marathon to focus your training through the summer and finish the year on a high!

- 15 mins read

5 ways for events to be more sustainable

Wooden medals, virtual medals and no medals at all - what does an eco-friendly event look like?

- 5 mins read

3 tips for training for an obstacle race

How do you prepare for a race designed to be unpredictable and, frankly, chaotic? By keeping your training varied and avoiding injury like the plague!

- 5 mins read

3 ways to spend more time outdoors

Need some extra motivation to get lace up those boots and get out there? It happens to all of us - but overcoming that inertia and spending time outdoors is the best possible decision you can make!

- 8 mins read

7 incredible coastal walks in the UK

Discover some of the best coastal walks in the UK, from the wild shores of Arran to the rolling hills of the South Downs.

- 5 mins read

4 reasons why the Hackney Half is the ideal charity challenge

Fusing fast running with an electric atmosphere and community spirit, the Hackney Half celebrates the very best of East London.

- 12 mins read

What is the best marathon for running a PB?

Chasing a fast marathon time is as much about picking the right course as training hard! Check out our selection of the fastest and flattest marathons in the UK.

- 10 mins read

3 reasons to start open water swimming

From cold water therapy to time spent in the great outdoors, open water swimming is your express ticket to feeling happier and healthier this year.

- 5 mins read

3 reasons to run an obstacle course race for charity

Elevate your race day experience by raising money for a great cause, connecting with other people and enjoying a discounted entry fee!

- 10 mins read

Why is the Great Manchester Run the biggest 10K in Europe?

With thousands of runners taking part each year, this headline race is Manchester's original and greatest running event - here's why you should be there in 2024!

- 5 mins read

5 things you need to know before your first ultra

Ultra marathons are some of the greatest tests of endurance on the planet and yield unforgettable experiences - if you're well prepared.

- 5 mins read

Run a marathon for charity

Whether it's your first or fifth marathon, entering a 26.2-mile race on behalf of a charity will elevate your experience! Here's how to get started.

- 10 mins read

Enter your first triathlon

This dynamic multi-sport will test your speed and stamina, providing an incredible experience along the way! We've got everything you need for your first swim-bike-run right here.

- 10 mins read

Dive in: how to start open water swimming

From sea swimming to an ice bath in your garden, cold water is having a moment. Diving into open water swimming helps you feel healthier and happier - we've got everything you need to get started.

- 10 mins read

Running your first marathon

Signing up to run 26.2 miles for the first time will be one the most rewarding decisions you ever make! This guide has everything you need to get started, from training tips to a basic kit list.

- 5 mins read

Run a half marathon for charity

Taking on a half marathon on behalf of a good cause could be exactly the challenge you need! This is all the information you need to get started.

- 10 mins read

Cross-training for runners

Weightlifting, bodyweight exercises and yoga all have a place in improving your running form and staving off injury. This is your complete guide to cross training for runners.

- 10 mins read

Running your first half marathon

Signing up to a half marathon for the first time can be both exciting and daunting in equal measure! This guide will run you through how to train for it and what to expect on the day.

- 5 mins read

How long is a half marathon anyway?

The short answer: 13.1 miles. Understanding what that looks and feels like isn't that simple, though, so we've set out what it's like to run a half marathon bit by bit!

- 5 mins read

Running kit to wear in the dark

Just because the nights draw in doesn't mean you need to head indoors - with the right clothing and equipment, you can keep running through the winter!

- 10 mins read

What is the best half marathon near me?

Looking for a half marathon this year? This is your guide to the best half marathons in the UK, organised into regions so you can find a race near you!

- 10 mins read

10K tips for beginner runners

This popular distance is great for both racing and exploring local trails, but where do you get started? Well, right here.

- 3 mins read

5 reasons to run the Virtual TCS London Marathon

Whether or not you entered the ballot for the TCS London Marathon, the virtual edition is a fantastic event with plenty to offer. Here's what we learned!

- 5 mins read

Your guide to the BMW Berlin Marathon

Considered to be the fastest marathon in the world, Berlin is a brilliant choice for any runner, whether it's your first 26.2-mile race or you're looking for a PB!

- 5 mins read

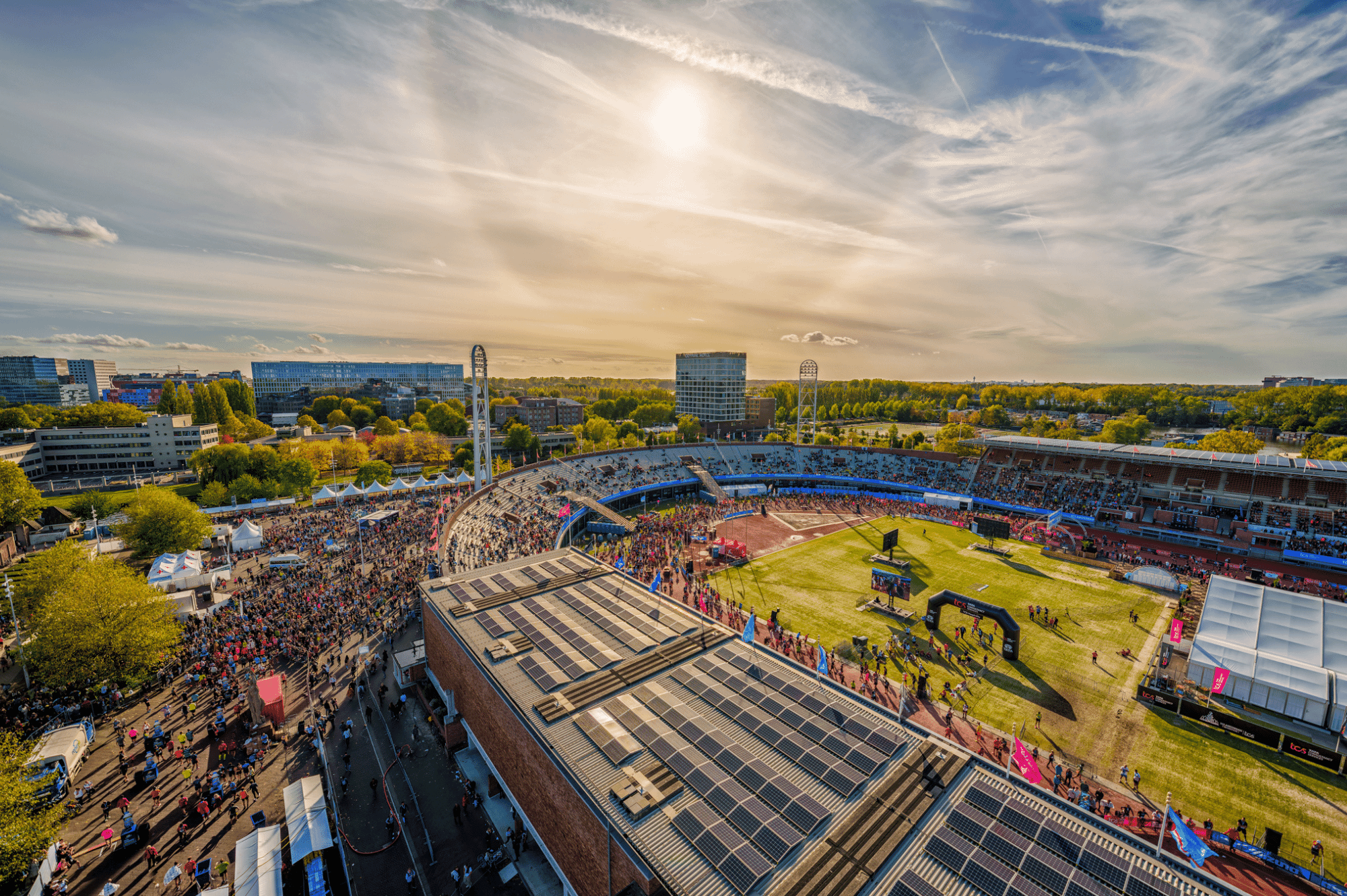

Your guide to the TCS Amsterdam Marathon

One of the fastest marathons in the world, Amsterdam is a brilliant fusion of a great running experience and a superb cultural immersion. This is everything you need to know!

- 10 mins read

The beginner's guide to duathlons

Run-bike-runs aren't just for triathletes in the winter - they're a serious multi-sport discipline in their own right, getting people active outdoors on road and trails alike.

- 5 mins read

Your guide to the Paris Marathon

The second largest marathon in the world, the Schneider Electric Paris Marathon attracts 65,000 runners to the French capital for an incredible route and an international EXPO.

- 5 mins read

Your guide to the London Landmarks Half Marathon

The only half marathon to run through Westminster and the City of London, this is a fantastic race touring the capital's most iconic landmarks. This is everything you need to know about the race!

- 5 mins read

What to wear for trail running

Adventure, exploration and freedom are at the heart of what makes trail running so addictive - to make sure you're getting the most from your experience, get kitted up and be trail-ready.

- 5 mins read

The best places in the UK for trail running

We're spoilt for choice when it comes to off-road routes in the UK but if you're looking for some inspiration, this is where you'll find it!

- 5 mins read

Everything you need to know about trail running shoes

Lugs, rock plates and cushioned midsoles - what are they and why do you need them?

- 10 mins read

The beginner's guide to trail running

Off-road running is on the march, with new races being announced and more people keen to escape the hustle and bustle of modern life. This is everything you need to know to get involved.

- 10 mins read

Your guide to the Edinburgh Marathon

Alongside the headline 26.2-mile run, there are eight other races to choose from at this vibrant festival in the Scottish capital.

- 5 mins read

Your guide to the adidas Manchester Marathon

Known as one of the UK's fastest, flattest and friendliest marathons, this popular 26.2-mile race attracts thousands of runners each year to the North West's biggest city.

- 5 mins read

Race 101: the TCS London Marathon

The biggest marathon in the UK - and one of the biggest in the world - is an event that every runner wants to tick off their bucket list. Here, we deal with the most-asked questions on the web!

- 5 mins read

Run for charity in the TCS London Marathon

This iconic event is always oversubscribed at the ballot but there are plenty of charities to run for and plenty more reasons to do so.

- 5 mins read

Your guide to the TCS London Marathon

This is the UK's biggest marathon and one of the greatest in the world - here's what you need to know!

- 5 mins read

The top 25 events in the UK

These mass participation runs, bike rides and triathlons are the most popular outdoor events for a reason!

- 5 mins read

Why spending time outdoors is essential

Whether it's a grand adventure or a humble walk in the woods, being active outdoors is the best thing for your health and happiness - here's why.

- 5 mins read

Great North Run: the complete race-day guide

First GNR or chasing a PB? Here’s your at-a-glance route brief, start-line plan, pacing tips and race-day logistics.

- 10 mins read

13 reasons to run the Great North Run

Electric crowds, the Tyne Bridge roar and a finish by the sea - here’s why GNR belongs on your bucket list.

- 5 mins read

How to get a Great North Run charity place (step-by-step)

Missed the ballot? Follow this plan to secure a guaranteed place and raise funds for a cause you believe in.